DESCRIPTION

The bending unit of a rotogravure printing machine for publishing is equipped with a complete cutting unit of many slitters for the division of the printed reel in ribbons, which then give rise to the pages.

This section of the machine generates a huge amount of paper dust with hazardous consequences, because there are installed electrostatic charging bars which may ignite the paper dust and irreparably damage the machine, not to mention the hazards to personnel and the burden of maintenance costs arising from the presence of paper dust very abrasive in the mechanical parts of the bending castle.

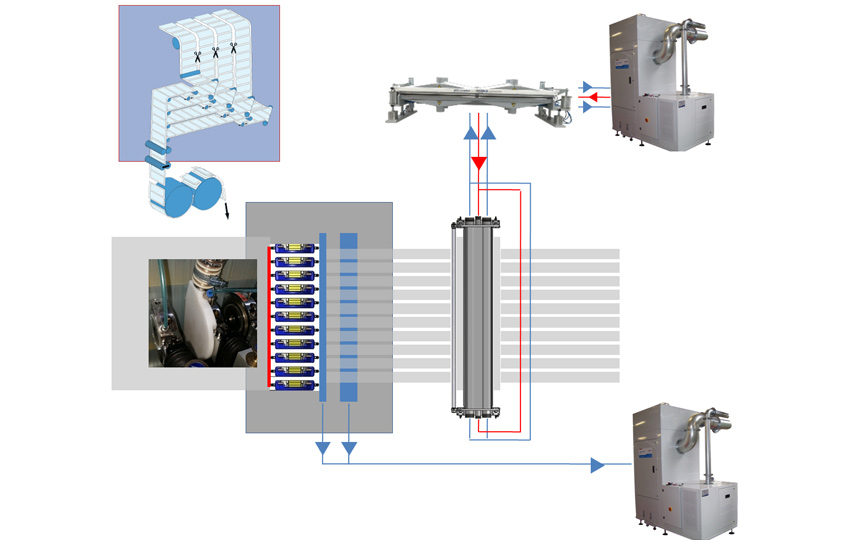

This ACE solution consists of three elements:

- The containment little hoods of the knives that suck the dust generated by the cutting

- a cleaning head that activates before the cut ribbons enter into the angular group of bars, where due to the separation they release the fibres partially trapped by completing the removal of paper dust

- a filter unit of appropriate size to meet the needs of the system. This unit can also transfer the collected dust to the centralized suction system already installed at the company.

CUT CLEANER safer bending machines and reduced maintenance costs.

.

THE ADVANTAGES

HC24 cleaning head and SPB91A2 filtering unit to remove any trace of dust on Cutting-Creasing lines

Process

Process

Each knife is enclosed in a special hood equipped with powerful ventilation system on the blade and large suction volume; ACE brilliantly solves the problem of dust and fibres from the cutting unit.