DESCRIPTION

Great advantages during production with Series AR Contact Systems. They remove 100% of contaminant particles (up to 0.5 microns), ensure that the tape at the input of the printing unit does not release dust that can result in a reduction in quality. The on-line cleaning of the converting machines guarantees finished products free from contamination.

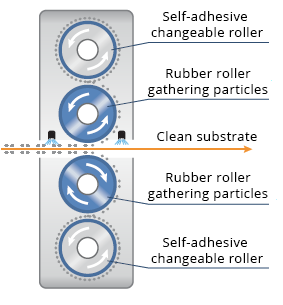

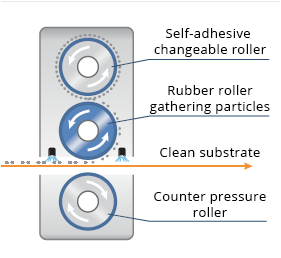

At the input of the AR unit an antistatic bar eliminates the static charge of the material, thus releasing contaminating particles that were there anchored. Special rubber rollers attract dust, during their contact (on one or two sides) with the material, which is then collected by adhesive rollers in contact with the rubber rollers.

The rubber rollers remain constantly clean, but with intervals that vary, depending on the degree of soiling of the material, the outer layer of the adhesive rollers will be removed, leaving the underlying one again ready to hold new dirt. At the input of the AR unit is mounted a second antistatic bar to eliminate any residual static charges.

THE ADVANTAGES

| MODEL | web width | Flexible packaging paper (coated paper) | Flexible packagingFlm and Foil | Labels | Printing and Converting | Pharma |

|---|---|---|---|---|---|---|

| AR 700 1S - 2S | (250 ÷ 700 mm) | ⚫️ | ⚫️ | ⚫️ | ➖ | ⚫️ |

| AR 800 1S - 2S | (250 ÷ 800 mm) | ⚫️ | ⚫️ | ⚫️ | ➖ | ⚫️ |

| AR 850 1S - 2S | (400 ÷ 850 mm) | ⚫️ | ⚫️ | ⚫️ | ➖ | ⚫️ |

| AR 900 1S - 2s | (600 ÷ 1.200 mm) | ⚫️ | ⚫️ | ⚫️ | ⚫️ | ⚫️ |

| AR 1000 1S - 2S | (900 ÷ 1.600 mm) | ⚫️ | ⚫️ | ➖ | ⚫️ | ⚫️ |

| AR 1500 1S - 2S | (1.000 ÷ 2.000 mm) | ⚫️ | ⚫️ | ➖ | ⚫️ | ⚫️ |

OUR PRODUCT

THE PROCESS

Process

1. Iondual 24V static charges elimination at entrance

2. Dust particle removal by means of rubber rollers

3. Dust particles transfer to adhesive rollers

4. Iondual 24V static charges elimination at exit

1 side cleaning

2 sides cleaning