DESCRIPTION

Any cutting unit generates dust and this is a fact.

Any cutting unit generates dust and this is a fact. Dust and fibres are entrained on the materials after cutting, then remaining imprisoned in the reels during winding. The contaminating dust and fibres accumulate in the knives unit, both on the blades and in their vicinity, settle on the materials before winding and give rise to final reels with incorrect thickness, and expensive material waste for non-compliance.

In fact, the dust and fibres trapped in the reels will be released again by the subsequent unwinding process on other lines, certainly influencing the quality of the finished product. In addition the dust adhering to the blades generate thickness that interfere with the quality of the cut, which according to the type of material may even result in breakage of the strips leading to production stoppages.

The installation of a CutCleaner system on the cutting unit completely eliminate these problems, besides increasing the service life of the knives in a remarkable way.

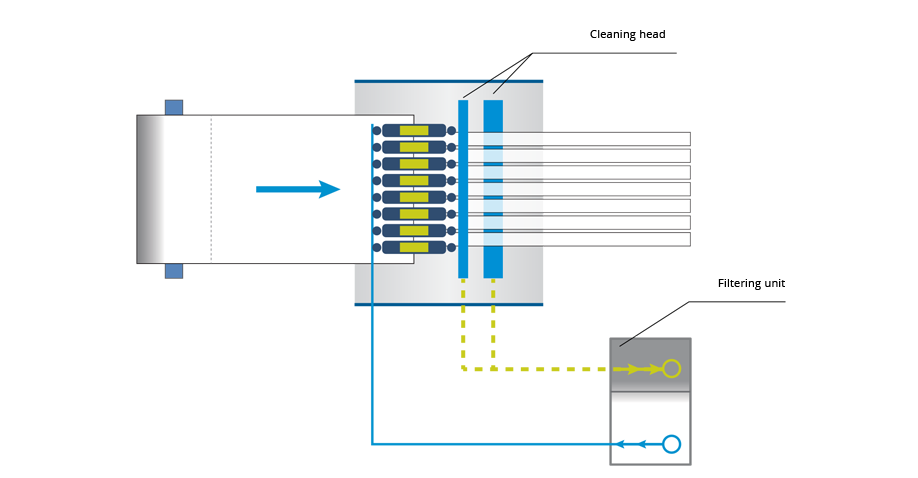

The combination of a CutCleaner and Dedusting “non-contact” system of the DM series including an adequate filtering unit, represents the state of the art in applications for high dustiness materials such as paper, cardboard, tissue and

THE ADVANTAGES

HC24 cleaning head and SPB91A2 filtering unit to remove any trace of dust on Cutting-Creasing lines

Process

Each knife is enclosed in a special hood equipped with powerful ventilation system on the blade and large suction volume; ACE brilliantly solves the problem of dust and fibres from the cutting unit.