DESCRIPTION

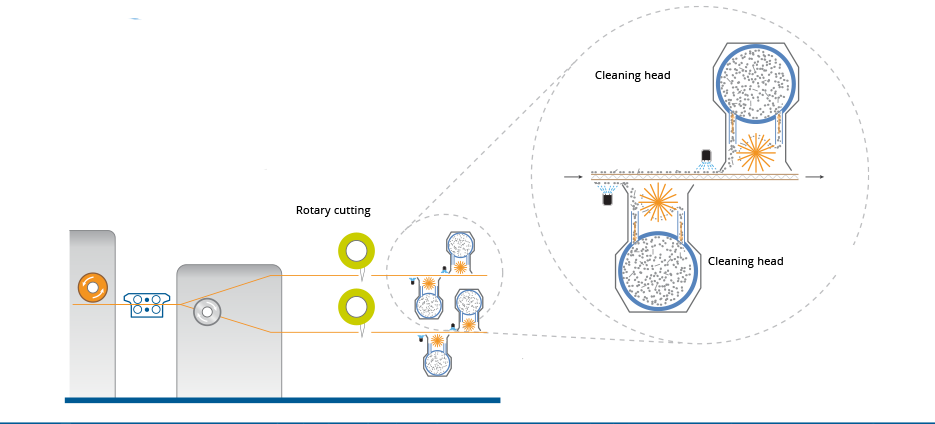

In corrugating machines the comes next to the Cutting-Creasing machines is the cross cutter. In this section, the strips resulting from the longitudinal cutting of the parent reel are reduced into sheets. It is no longer therefore to eliminate the dust from a reel, but from sheets. Thanks to the dedusting system ACE COR-TR28 model, each individual sheet is completely freed from the paper dust generated by cutting.

The system consists usually of two cleaning heads, an upper and a lower one, placed one after the other. These special heads are equipped with a 24V low voltage anti-static bar with high efficiency, to eliminate the electrostatic bond that retains the impurities on the surface of the cardboard. Inside the head are placed suction channels for high volumes of air, and a special rotating brush fitted with bristles specially designed to intercept any type of contaminant. The aerodynamics and combined mechanical action makes it possible to completely remove any remaining dust.

The plant is completed by high-capacity filtering units, accompanied by appropriate ducting of rigid pipes and prepared ad hoc for each type of installation.

THE ADVANTAGES

A Cleaning Head model HC50 for each side of the sheet and a Filtering Unit SPB of large dimensions to eliminate any trace of dust from the cross cutting units on corrugating lines.

Process

1. Elimination of static charges through the BB-Iondual 24V bar

2. Removal of dust and scraps through the rotating brush

3. Suction of contaminating particles