DESCRIPTION

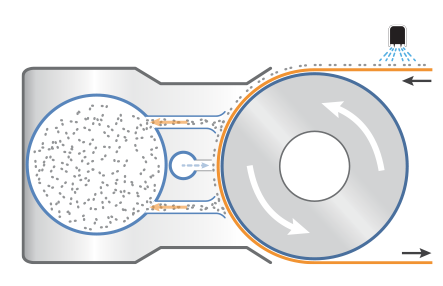

The AK2000-TU system guarantees the removal of large- or small-sized contaminants. It must be installed ontube sheetsbefore the the tapes coupling sector, in combination with a sliding roller of the paper band that serves to guide the tape inside the device.

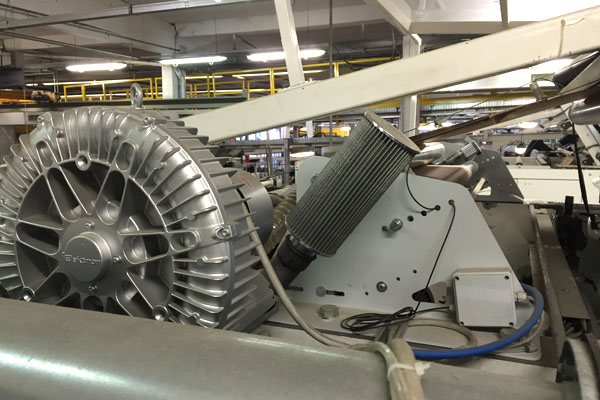

First of all it is eliminated the electrostatic charge present in the paper. Immediately after, within the structure of the AK-2000-TU isgenerated a great turbulence, in a combination of blowing and suction of large volumes of air. The filtering unit of the new SPB93 generation generates the required airflows and is equipped with self-cleaning filters and drawer for contaminant collection. The unit is connected to the cleaning head through rigid pipes and hoses.

AK2000-TU is the best solution to guarantee a production absolutely devoid of any type of contaminant, it is continuous and without any need for manual product control, or elimination of bags not perfectly cleaned by the operator. Its use makes it unnecessary to equip the line with systems for the detection of contaminants..

THE ADVANTAGES

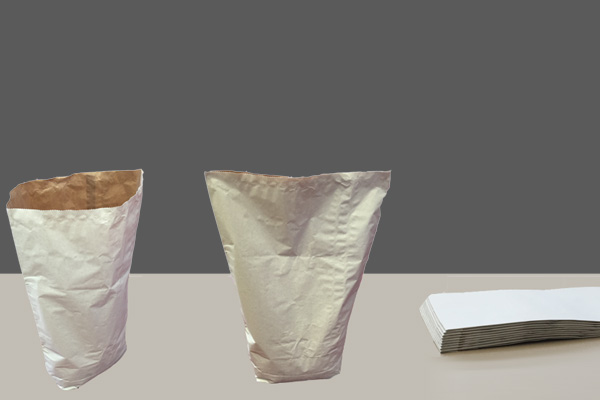

The finished product is formed from various layers, which benefit from the dedusting treatment.

This ensures the elimination of impurities and allows not to provide further contaminant detection controls

This ensures the elimination of impurities and allows not to provide further contaminant detection controls

THE PROCESS

Process

1. Removal of static charges thanks to the use of IONDUAL 24V antistatic bar

2. Dust lifting up by means of air blades

3. Contaminant particles vacuum away