Process

Rotogravure printing

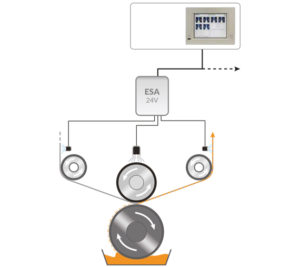

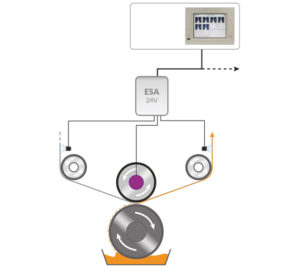

During the rotogravure printing process the problem that most often adversely affects the print quality and ink consumption is the “Missing points”. This occurs when the ink in the cells of printing cylinders hardly exit completely and consequently does not reach the substrate to be printed, whether it is paper or film. The new and patented 24V ESA system in versions Top Loading and Direct Charging is the solution by ACE to this problem. In fact, thanks to the correct polarization of the ink through the influence of proper electrostatic charge applied to the pressure, the ink migrates towards the substrate completely. It is thus obtained a high-quality printing with a great ink saving.

To all this is added the Research by ACE which created an ESA system completely 24Volt powered, so that in addition to the performance guarantees a safety level not achievable by other systems.

In rotogravure printing of editions, which is necessarily equipped with ribbons folder, ACE has developed a special system to ensure the electrostatic adhesion of the tapes after the longitudinal cut, before the cross cut. This is a further technological innovation that ensures high performance and a homogeneous electrostatic charge over the entire length of the printed page.

ACE Products

Contactless web cleaning systems

New 24V Antistatic Bars

Static Charging Bars

ESA Electrostatic Assistance to Gravure Printing 24V

Static Charging Bars

Systems and Technologies