DESCRIPTION

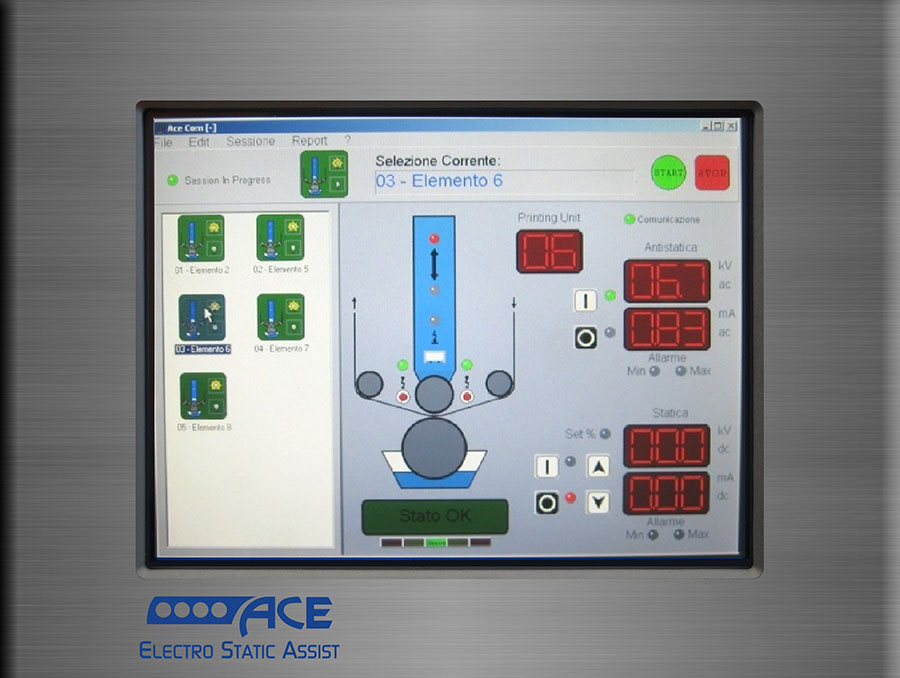

ACE Genius is the most advanced ESA facility management software on the market today, implemented by ACE on the ASC44 / T Remote Control panel, which can be installed on rotogravures control desk to keep under control the wide range of features offered by Genius. Genius is divided into different menus that appear on the 8.4” monitor, supplied as standard and which optionally can also be offered in either 12″ or 15″, according to Customer requirements.

In each page the printing elements equipped with the ACE system installed are shown, as well all the operating values of each ESA element. The special program for Recipes, allows at the end of each production cycle to store the values set for that specific work by assigning a specific code, so you can reset the system when that work cycle is to be repeated. A log menu including a list for storing Alarms and Events is available, as well as several other menus and functionalities, related for example to the line safety, thanks to which the ASC44/T system can be effectively interfaced with other signals from the rotary press. Selection of the printed material: important menu that allows the selection function between paper, PET and other types of films. For each material selected for production, the system is set on ESA appropriate operating values for each printing unit, so as to ensure maximum print quality without thereby exceeding the allowed power limits.

DESCRIPTION

Although ACE AST 44/T is a sophisticated system, its use is simple and intuitive and is much appreciated by operators who, through choice options can work for:

The ACE ESA system, thanks to the Genius technology, can be monitored and serviced remotely via computer.

SCT System (Sleeve Control Technology)

This device automatically controls the conductivity of the sleeve, warning about possible alarms in case it would not be within the required range. SCT also prevents the system to operate in case a wrong sleeve has been installed on the pressure roller.

ASCT44T